Recently, our basement got flooded. That in itself is a story and a half, but I won't go into that. Suffice it to say that the water just managed to get over the edge of the sump pump well and then wicked through all the carpeting throughout the basement. So all the carpeting had to be removed (it was a load a crap anyway) and we are now back down the the bare concrete floor.

That floor is in remarkably good shape. It is even, with only some hairline cracks here and there. No spalling or delineation anywhere, so that's good. However, it is cold. Very cold. Even this late in spring, the floor temperature hovers around 14 °C. So that's not good.

Now, as we all know, hot air rises and cold air sinks, so theoretically, that cold air doesn't readily mix with the warmer air at higher elevations. Therefore, the heat loss through the floor is a lot less than if, for instance, the ceiling were at 14 °C . Nonetheless, some loss must occur. Furthermore, especially this time of year, warm, moist air from outside enters the house, gets into the basement where it cools, causing the humidity to skyrocket down there. This, in turn, forces us to run the dehumidifier, which is noisy, hard on the hydro bill and needs periodic maintenance.

So I started looking for a solution to these problems. Rather than just taking a wild guess (or doing some research and doing a best guess), I decided to get all scientific, by setting up tests with different materials and options to insulate the basement floor.

Design criteria:

- warmer basement floor

- lower humidity level

- ease of installation of the product

- cost

- small loss of headroom

Products to test

- Dricore

Dricore (

www.dricore.com ) consists of half an inch OSB glued onto a polyethylene sheet, from which cleats protrude, allowing air to circulate under the floor, to remove humidity. Total thickness is 7/8" or 22 mm. It comes in squares of 2' x 2' (61 x 61 cm), which have a tongue and groove. The tile is put down and the next one is tapped into the groove to complete the assembly.

The manufacture claims an insulation value of R-2

Cost: $ 6.99 per tile

- OvrX

OvrX (

www.ovrx.com ) is 1/2" Styrofoam mechanically bonded to 5/8" OSB. The styrofoam has grooves cut (or ground might be a better term) on the bottom, to allow for air and moisture to pass through. Total thickness is 1 1/8" or 29mm.

It, too, comes in squares of 2' x 2' (61 x 61 cm), which have a tongue and groove. As above, assembly is through the tongue and groove system, no screws are driven into the floor.

The manufacture claims an insulation value of R-3.2

Cost: $ 7.99 per tile

- 1" (25 mm) Styrofoam sheets (2' x 8' or 61 x 244 cm) overlayed with 4' x 8' ( 122 x 244 cm) sheets of OSB or plywood. Pilots holes are then drilled through the plywood, the styrofoam into the concrete floor and Tapcon screws are then driven into these holes. No picture for this, as I am sure you can well imagine what this looks like. Styrofoam would be R-5, with OSB .2 for a total of R-5.2

Cost: $ 13.11 per sheet of Styrofoam and $20.00 for OSB.

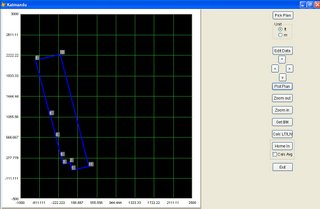

First, I wanted to test for the insulation values. So I set up a test bed, consisting of the material to be tested, the bottom portion of a picnic cooler, a 27 W soldering iron and a temperature monitor. I used the soldering iron, to get a nice steady heat source, which would be the same for all the tests. The temperature monitor comes from

http://www.ibuttonlink.com. It is a 1 wire device, which hooks up to the serial port on a computer, and reports the temperature every time the computer program requests it. I wrote a Visual FoxPro application that makes a request every 30 seconds and then logs the result into a database table.

Here is the setup, soldering iron on the left, temperature monitor on the right, spaced about 1', I mean 30 cm apart. In this case, they are positioned on top of the OvrX material.

Here's the complete setup, with the cooler positioned over top to minimize the influence of the ambient temperature. You can see the Dricore tile on edge on the left and a leftover piece of 2" (51mm) Styrofoam on the right. You could probably argue and say that, hey, there was an air gap caused by the wires forcing the rim of the cooler up, but my answer is that that applied evenly to all the tests, so the net effect was zero.

Next I ran the test for all the materials. Note that I only had a 2" (51 mm) piece of Styrofoam, since I had this left over and I was too cheap to buy a 1" piece. Basically what I did was, I put the material to be tested on the floor, put the soldering iron on it along with the temperature monitor, about 30 cm apart. I then put the cooler upside down over top and plugged in the soldering iron and started the monitoring and logging process. Once I saw that the maximum temperature had been reached (i.e. the temperature wasn't going up anymore), I unplugged the soldering iron and waited for the whole thing to cool down, still continuously logging.

I repeated this four times. Once for each of the materials tested and once just on the bare concrete floor. Then, I did some data manipulations and graphed the results using Open Office Calc (

www.openoffice.org ) Basically, Open Office is a free replacement for Microsoft Office.

The graphing turned out to be a huge pain in the neck, it would have been better to use my trusty old Graph NT ActiveX in Visual FoxPro, but hey it's done now, so who cares.

Here's the graph:

The 2" Styrofoam itself manages to drive the temperature all the way up to 53 degrees, whereas the bare concrete floor only makes it to 24 degrees. Quite a difference. The styrofoam backed OvrX makes it to 41 degrees, beating out Dricore, which gets up to 36 degrees.

AnalysisInsulation- OvrX scores significantly better than Dricore. A 1" piece of Styrofoam would obviously be best.

Cost (in Canadian dollars)According to the manufacturer's web site, I need 44 tiles for both Dricore or OvrX

- Dricore: 44 x $ 6.99 = $ 307.56

- OvrX: 44 x $ 7.99 = $ 351.56

- 1" Styrofoam/1/2"OSB = (11 x $13.11) + (5 x $20) = $ 244.21

Installation- Dricore and OvrX should be equal to each other here. Both should beat the combination of Styrofoam/OSB sheets handily. Handling large sheets of OSB over top fragile exposed Styrofoam, then drilling holes through all that into the concrete and driving screews does not exactly appeal to me.

Loss of HeadroomDricore comes out best here at 22 mm (7/8"). Ovrx is second at 29 mm (1 1/8"). Styrofoam/OSB last at a whopping 1 1/2" or 38mm.

ConclusionOvrX beats out Dricore in terms of insulation. OvrX also beats out the Styrofoam/OSB combination due to ease of installation. The cost is higher, but my blood pressure has got to be worth something. The difference in headroom between Dricore and OvrX isn't significant enough to make a difference. So that's it! On to the ordering stage.

Tomorrow, I'll install temperature monitoring in the room at eye level as well as floor level. Then we can do a before and after installation comparison, and see what difference there is.

Again, once you are on the regular, 3 lane portion of Hwy 403 towards Hamilton, stay in the second lane from the left, the middle lane. This takes you exactly to where you need to go. This picture shows where the Lincoln Alexander branches off from 403. About 2 km past this point, Hwy 403 narrows to 2 lanes. If you are in the middle lane, then you do not have to do anything.

Again, once you are on the regular, 3 lane portion of Hwy 403 towards Hamilton, stay in the second lane from the left, the middle lane. This takes you exactly to where you need to go. This picture shows where the Lincoln Alexander branches off from 403. About 2 km past this point, Hwy 403 narrows to 2 lanes. If you are in the middle lane, then you do not have to do anything. You can breathe a sigh of relief now: traffic should get a lot lighter. From the Lincoln Alexander to Hwy 24 South to Simcoe is about 40 km. You'll pass through the city of Brantford. Note that there is also a Hwy 24 North exit, you do not wish to take that. You'll end up in Cambridge.

You can breathe a sigh of relief now: traffic should get a lot lighter. From the Lincoln Alexander to Hwy 24 South to Simcoe is about 40 km. You'll pass through the city of Brantford. Note that there is also a Hwy 24 North exit, you do not wish to take that. You'll end up in Cambridge.

Hwy 24 can be divided in roughly three parts. The first part is done when after about 10 km, you reach a set of traffic lights. At the green light, drive straight through to the next set of lights (about 15 km). Once again, keep going straight. After that, at about 2 km, you will see the blue 'Norfolk County" sign. You are getting close!

Hwy 24 can be divided in roughly three parts. The first part is done when after about 10 km, you reach a set of traffic lights. At the green light, drive straight through to the next set of lights (about 15 km). Once again, keep going straight. After that, at about 2 km, you will see the blue 'Norfolk County" sign. You are getting close! From here on in, you will start seeing signs, spaced 1.2 km apart, pointing to Windham Rd 2, 3,4,5 etc. (There are also Townsend Rd going left (east) but ignore those. ) The road you are looking for is Windham Road 12. It obviously follows Windham Rd 11. There is a green and yellow John Deere farm machinery dealership just past Windham Rd 12. If you miss the road, simply turn into the parking lot of the dealership and make your way back through this parking lot to its Windham Road 12 exit.

From here on in, you will start seeing signs, spaced 1.2 km apart, pointing to Windham Rd 2, 3,4,5 etc. (There are also Townsend Rd going left (east) but ignore those. ) The road you are looking for is Windham Road 12. It obviously follows Windham Rd 11. There is a green and yellow John Deere farm machinery dealership just past Windham Rd 12. If you miss the road, simply turn into the parking lot of the dealership and make your way back through this parking lot to its Windham Road 12 exit.